说明:

Introduction:

Waste management is a global issue with local impact, and reducing waste generation through prevention, reduction, recycling, and reuse is a core concern of the UN goals aimed at reducing the adverse per capita environmental impact of cities. Despite being a basic human need, waste management often receives lower attention than other utilities, which has expensive consequences for society and the economy.

India faces a pressing challenge, with 62 million tonnes of Municipal Solid Waste (MSW) generated annually, only 69% of which is collected, and a mere 28% treated, leading to open landfills. Aligned with the Paris Accord, COP 26 and the Swachh Bharat (Clean India) Mission initiated by the Prime Minister, Abellon, a pioneer in India's Waste-to-Energy (WTE) sector, aimed to process and dispose of 50-100% of the city waste, using controlled combustion technology, without the spread of odour, pathogens, or harmful emissions, which complies with MSW rule 2016 (initiated by Govt of India through Ministry of Environment Forest & Climate Change) and European Emission Norms. By addressing legacy waste issues, the project mitigates the release of harmful greenhouse gases associated with decomposing waste in dumpsites, contributing to climate change mitigation.

Scope and Criteria of the Project:

Indian Urban Waste is highly unpredictable on account of quantity and quality, with technological risk attached while processing it. Also, waste composition and quantities vary throughout the year due to weather changes. The technology developed for the WTE project addresses potential risks like lower productivity, more break downs, etc. The plant is an example of how such tailor-made design and engineering solution can make the technology successful, variable while following most stringent regulations and policies. Efforts have been made to mitigate weather-related risks by cooperation from multiple stakeholders.

The Design:

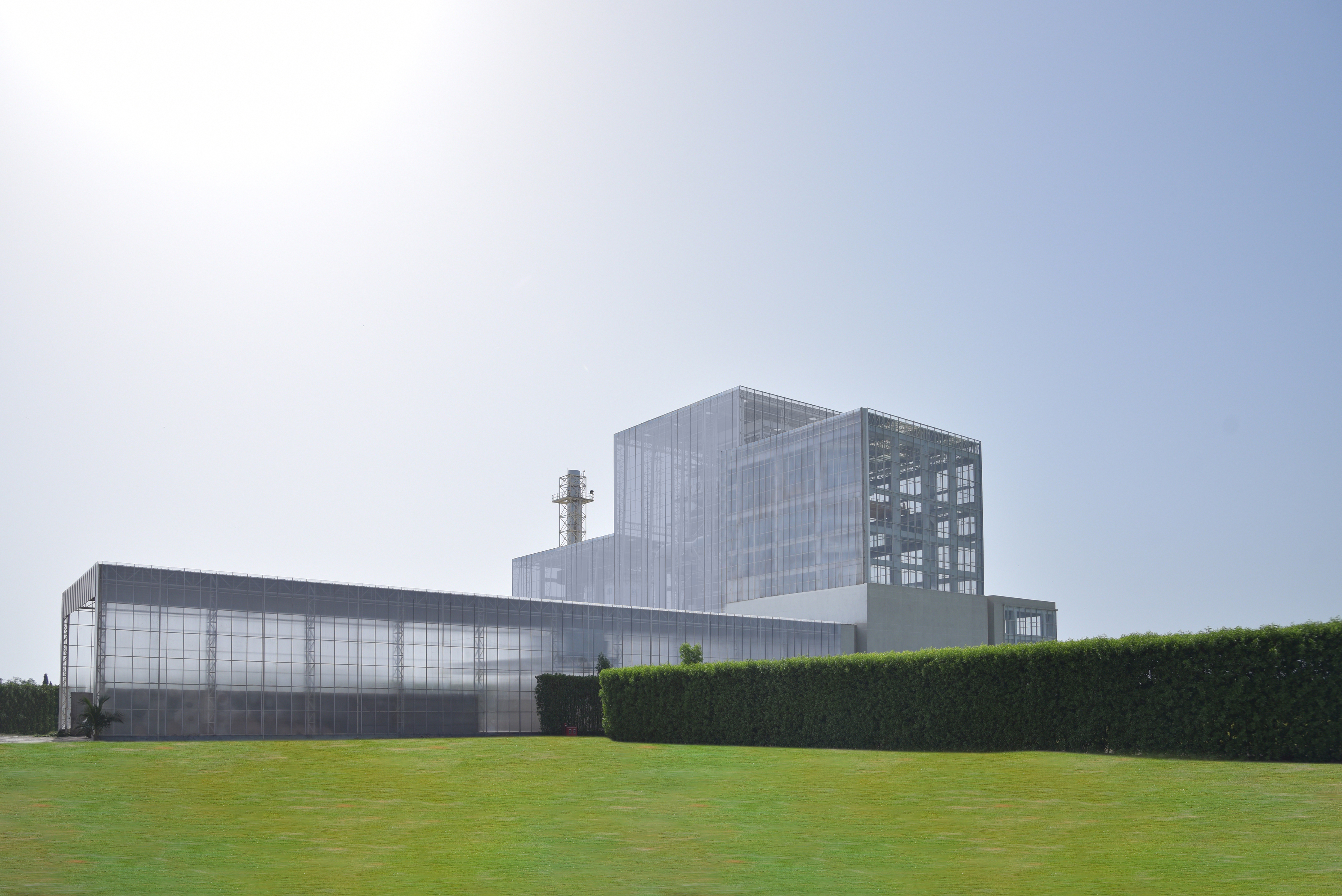

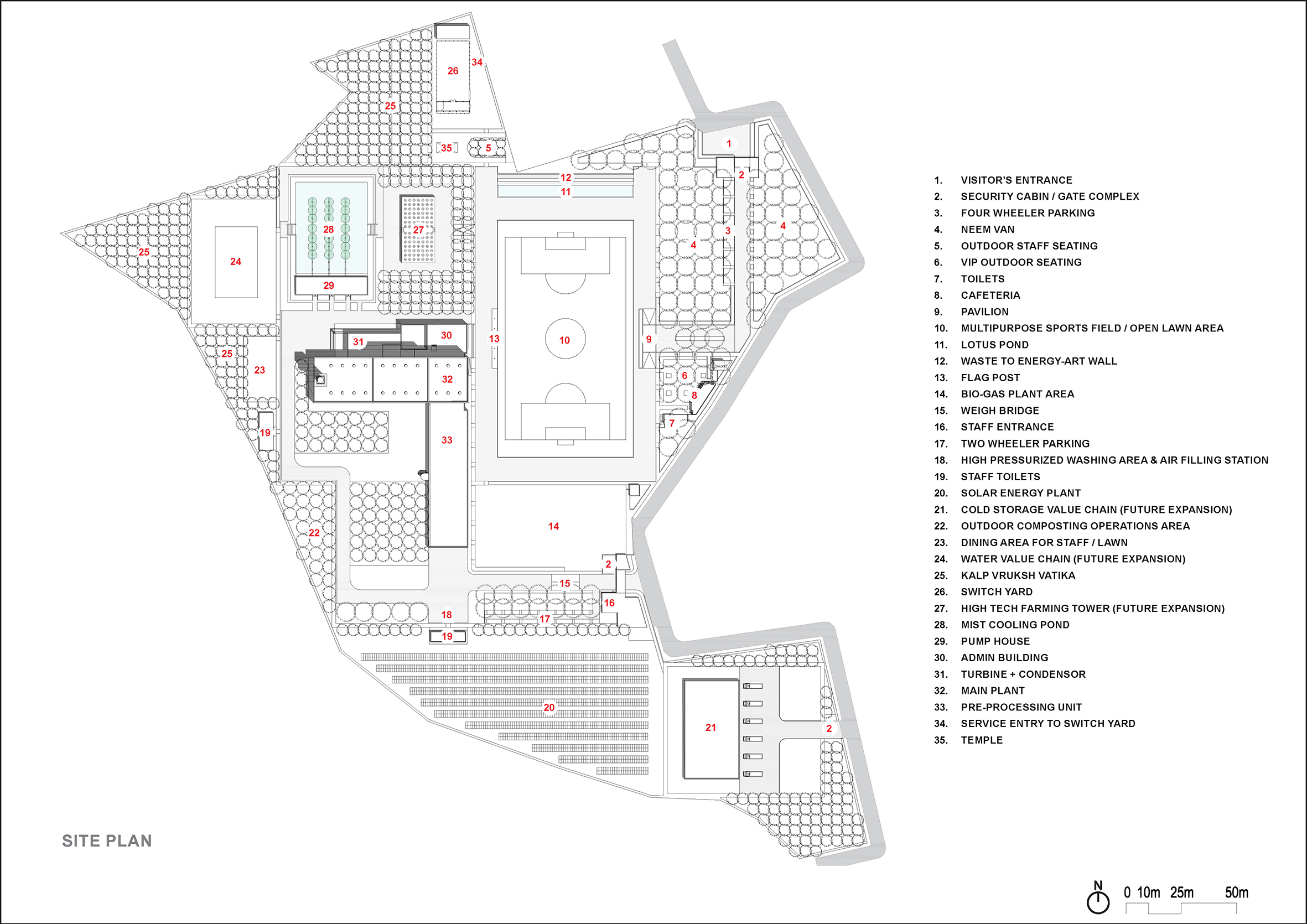

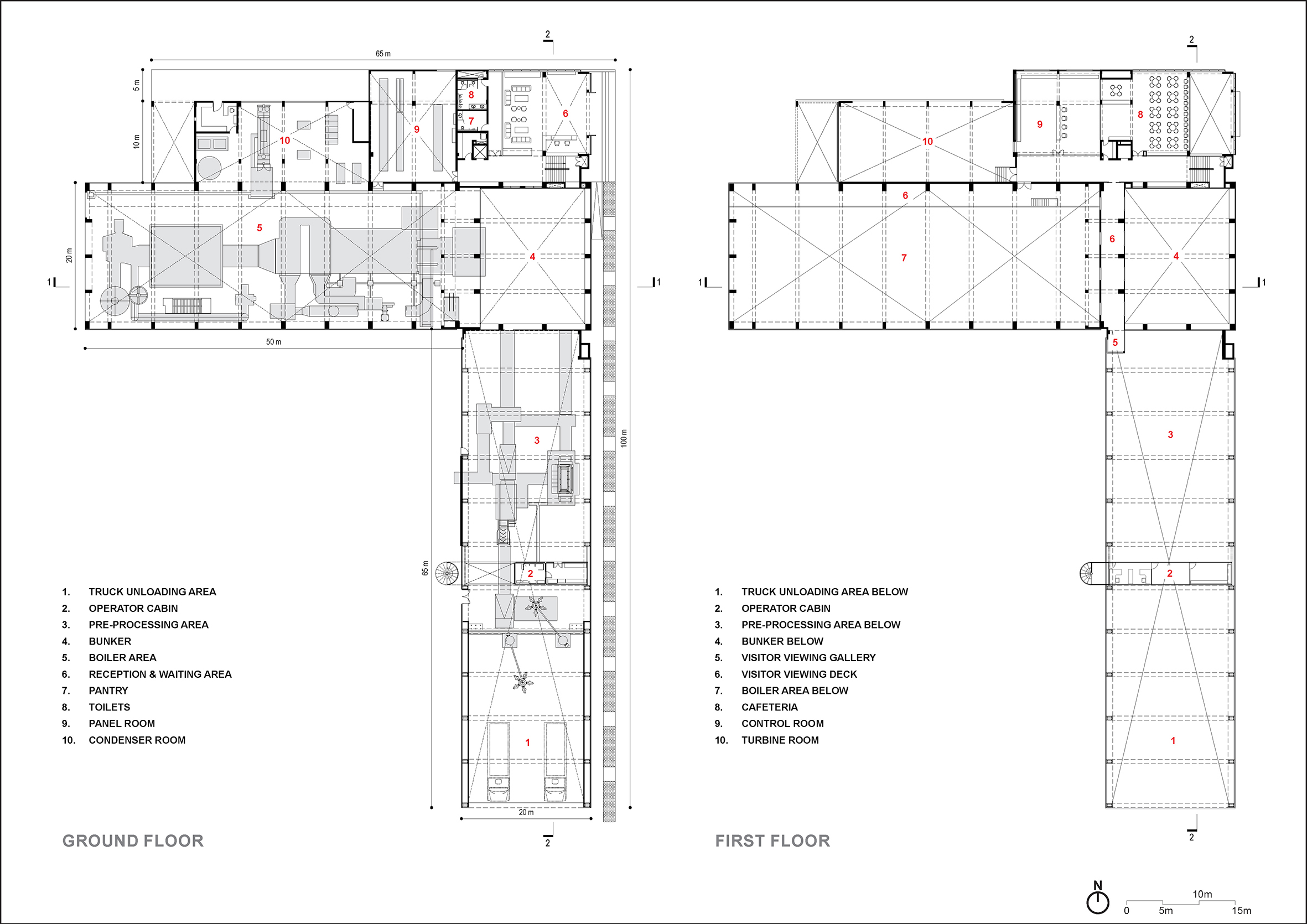

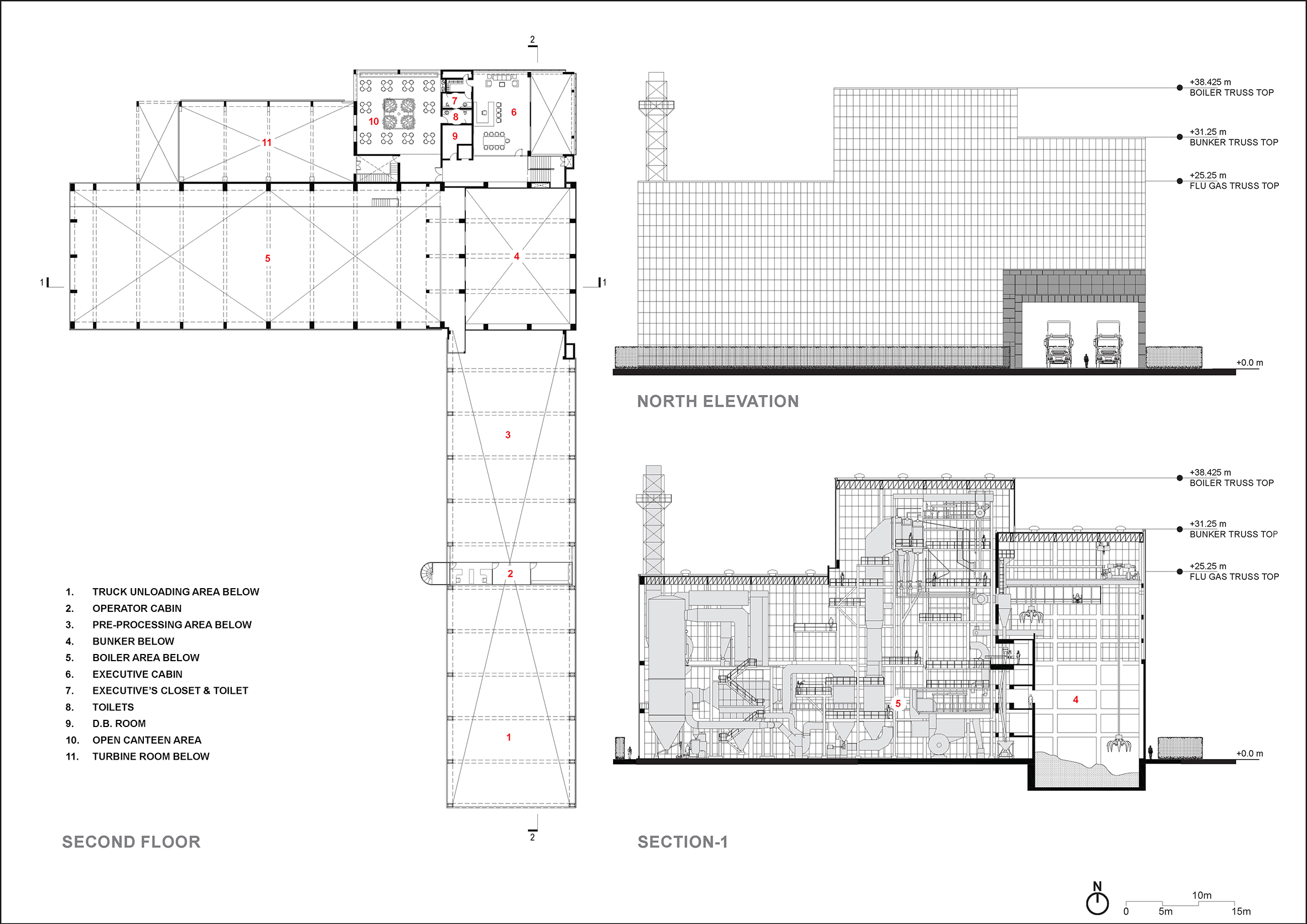

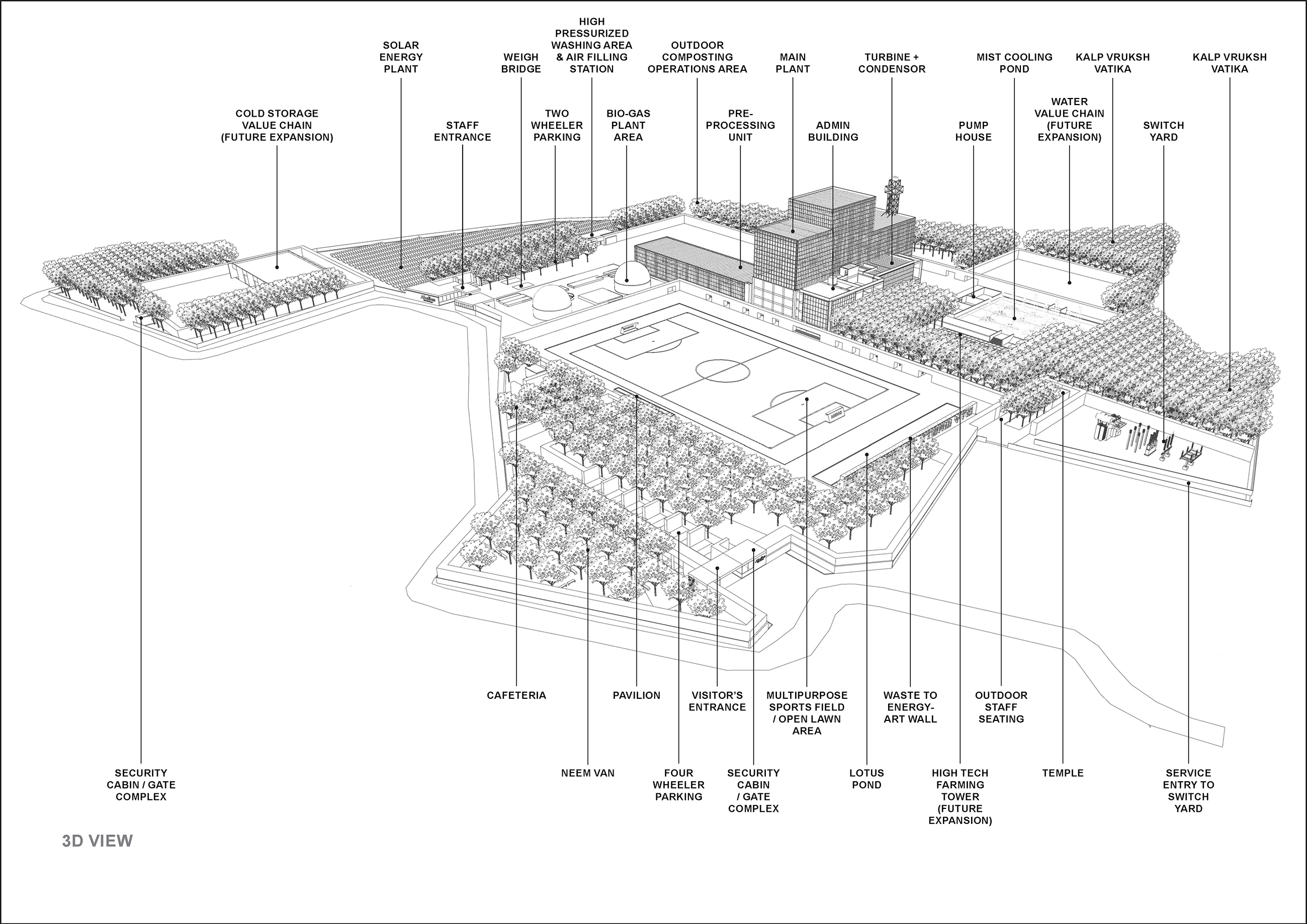

The 5,167 sqm Waste-to-Energy project converts 750 metric tons of municipal solid waste (MSW) per day into 7.5 megawatts of clean energy, enough to power 15000 homes, with zero toxic emissions, while transforming a 17-acre barren land into a greenbelt, with social infrastructure that include a jogging track, playfield, research and community spaces. Using only 20% of the site, the rest is reserved for community activities and future expansion. Designed for the Indian urban context in terms of type and quantum of waste generated, it involves almost no human interface during the entire process.

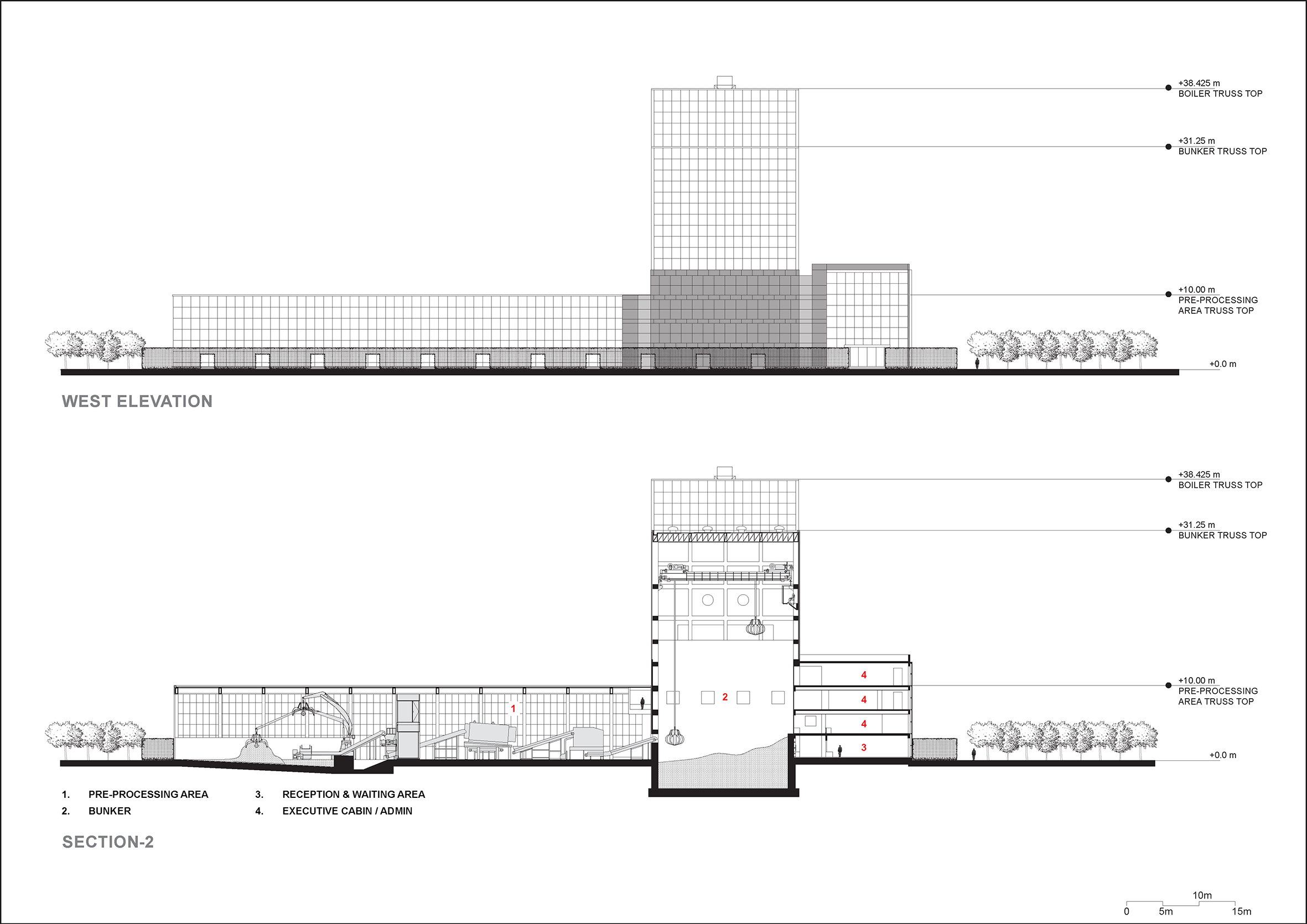

Adopting “form follows function”, the simple, open-span, lightweight prefab recycled steel structure optimises process flow by vertical stacking and sizing of the equipment. The translucent, recyclable multilayered polycarbonate façade system with a compact footprint, minimizes the surface to volume ratio, enhancing thermal performance, significantly reducing operational costs and energy consumption. Its light weight allows for efficient, easy installation and reconfiguration, and high strength renders it resistant to impact and fracture.

The building is designed to minimise energy load by integration of natural ventilation and natural lighting, while providing 100% protection from harmful UV rays. Translucent walls and roof panels provide enough filtered daylight for interiors, thereby reducing the need for artificial lighting and saving energy. Usage of high VOC paints, CFC based HVAC system and asbestos has been avoided to maintain better occupational health.

Use of Renewable Energy:

The master plan incorporates an onsite SolarPV with a capacity of 7.5 kW to meet 100% of the electrical needs for buildings and reduces reliance on conventional forms of energy, minimizing the consumption of fossil fuels for electricity generation. Through the generation of renewable power and the prevention of municipal solid waste (MSW) landfilling, the project achieves a substantial reduction in carbon emissions.

Integrating biogas plant that recycles garden waste and other wet waste from kitchens contributes to energy generation and reduces the dependence on fossil fuels for cooking and heating. Also, the project integrates eco-stoves that replaces LPG consumption.

Climate Change Mitigation:

The annual processing of about 2,20,000 tons of MSW in the plant generates 43.75 million units of green power and reduces the reliance on fossil fuels for electricity production, aligning with climate change mitigation strategies. Also, it is estimated to contribute to an annual CO2 reduction of 37,317 MT through renewable energy and landfill methane avoidance.

Efficient Design & Judicial Land Utilization:

The patented technology developed for the conversion of municipal solid wastes to usable forms of clean energy and other green by-products has remarkable set of advantages. Firstly, it is designed for the Indian urban context and customised for city waste characterization in terms of type and quantum of waste generated, and secondly, it involves absolutely no human interface during the entire process from start to finish. The plant (process flow) is oriented in such a way that incoming city waste has direct access to the plant and byproducts can be efficiently moved to the adjacent areas including bio-gas plant, optimising process flow and transportation.

Efficient design resulted in utilization of only 20% of the site area for the plant and related functions, allowing the maximum amount of land for community activities and future expansion. The design and technology integration results in minimum (to none) human interface, as well as spread of pathogens and foul smell to surrounding neighbourhood.

Wastewater Reuse:

Treated municipal wastewater is employed for various purposes within the campus, including advanced Mist Turbine Condenser cooling, which reduces the need for freshwater sources and auxiliary power for cooling. Mist condensers have the advantages of a longer working life, ease of operations, low maintenance, and economy, in comparison to conventional induced draft cooling towers. With the help of artificial intelligence modules Mist Cooling Systems ensure a constant cold-water temperature throughout the year, with a very low working pressure. A pipeline, 1 km long, is installed to source majority of process water requirement for cooling towers from treated municipal water, relieving pressure on freshwater sources. Additionally, a rainwater harvesting system captures 100% of runoff volumes through 10 recharge wells, promoting water conservation.

Green and inviting Campus:

Unlike the routine garbage collection landfills of most developing nations’ cities which are shunned and avoided by citizens on account of their stench and toxicity, this campus for waste processing is designed as an inviting campus which citizens can benefit from green social landscape and breathe fresh air. Efficient design resulted in utilization of only 20% of the site area for the plant and related functions, allowing the maximum amount of land for greens, community & sports activities, and future expansion. The entry points are segregated for trucks, staff and visitors.

Several landscaping strategies have been adopted to alter the microclimate of the site. Strategic placement of lush green 10+ feet tall trees hedge walls, native plantation and orchards, lotus pond and misting water pond all help filter harsh sunlight and mitigate the urban heat island effect. Orchards, green hedge walls and water bodies together guide cool breeze patterns by causing microclimate effect and pressure difference resulting in comfort. Landscaped area of about 37% of site area (10000 newly planted tress) is covered with drought- tolerant native species, promoting biodiversity.

Reduction of Marine & Water Pollution:

It has a direct impact on reducing ocean pollution, particularly in a coastal city like Jamnagar. By processing non-recyclable plastics within the MSW, approximately 22000 tons of plastic pollution that could enter the ocean is prevented. The project actively addresses water pollution by utilizing around 1 MLD of treated sewage water for operational requirements. In a city like Jamnagar, which generates approximately 50 MLD of sewage water, the safe use of this treated water significantly reduces pollution in nearby ground water, oceans and rivers. This practice enhances environmental governance by promoting responsible and sustainable water management practices.

Circular Economy Generation:

The campus master plan actively explored opportunities to enhance the circular economy by creating additional value chains in Waste-to-Energy sector. These include producing BioCNG from organic MSW content, recovering recyclable plastic from heterogeneous MSW, exploring green chemical production from specific MSW components, co-firing eligible industrial waste, and setting up facilities to convert fly ash into finished products such as green construction blocks and pavers. These initiatives reduce waste and enhance resource efficiency, indirectly reducing the need for fossil fuel-intensive manufacturing processes leading to circularity.

Land Conservation:

Conventional waste disposal practices need large tracts of land to dump municipal solid waste. As per estimates/model, 50 acres of land can be conserved, considering average 10m height of dumpsite for 20 years, thereby avoiding the establishment of large dumpsites. This land conservation aligns with sustainable land use and climate change mitigation efforts.

Public Awareness Programs:

By conducting mass awareness programs, the project aims to instil discipline in citizens for waste segregation at the source, reduces the operational challenges associated with unsegregated waste, contributing to effective environmental governance. Design focus expanded to offer opportunities to host educational trips and research platform for curious young minds in the related fields. This not only enhances the viability of waste processing units but also increases the degree of circularity in society.

查看更多

打开微信扫一扫

打开微信扫一扫